The Future is Automation

The average age of a skilled trades worker in North America is over 50!

Many young people want tech jobs.

Un-skilled labour increases accidents and waste, driving up project costs and increasing build times.

This has all contributed to the current housing crisis.

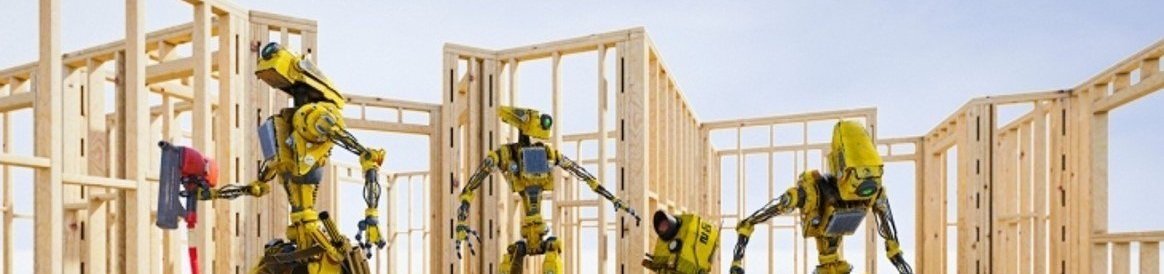

At PLAEX we believe that automation is about to transform our world, in a shift bigger than the automobile and the smart phone combined.

We are developing all of our products and equipment with the principles of industry 4.0 allowing for instant data feedback and automated process improvement with networked devices.

Our products are perfectly suited for integration with autonomous construction, allowing for faster build times than 3D printing, plus there is no cure-time. True Circular-Economy & full lifecycle design from day #1, through simple assembly & disassembly, reuse, and easy modifications, meaning simplified renovations and remodeling.

Humanoid Robots

& Construction Robots

The Future of automation is here today. From 3D Printing to robotic placing arms to Humanoid robots. There are many companies now using robots in warehouses and on factory floors near you. Automation and cooperative robots are no longer science fiction.

Here are just a few of the companies paving the way to the sci-fi future we are now entering. We are very excited to watch their development closely and we look forward to partnering to begin automating the installation of PLAEX projects as we grow.

3D Printed Houses:

Speed: 3D printers can significantly reduce construction time and may save costs in certain cases

Sustainability: The process generates less waste and uses fewer materials.

Customization: 3D printing allows for unique and tailored designs.

Cons: The two major downfalls of 3D printing are curing times and the inability to renovate

Robotic Bricklaying

Hadrian X® is the world's first mobile robotic bricklaying machine and system, capable of safely working outdoors in uncontrolled environments with speed and accuracy.

Hadrian X® builds block structures from a 3D CAD model, producing far less waste than traditional construction methods while dramatically improving site safety.

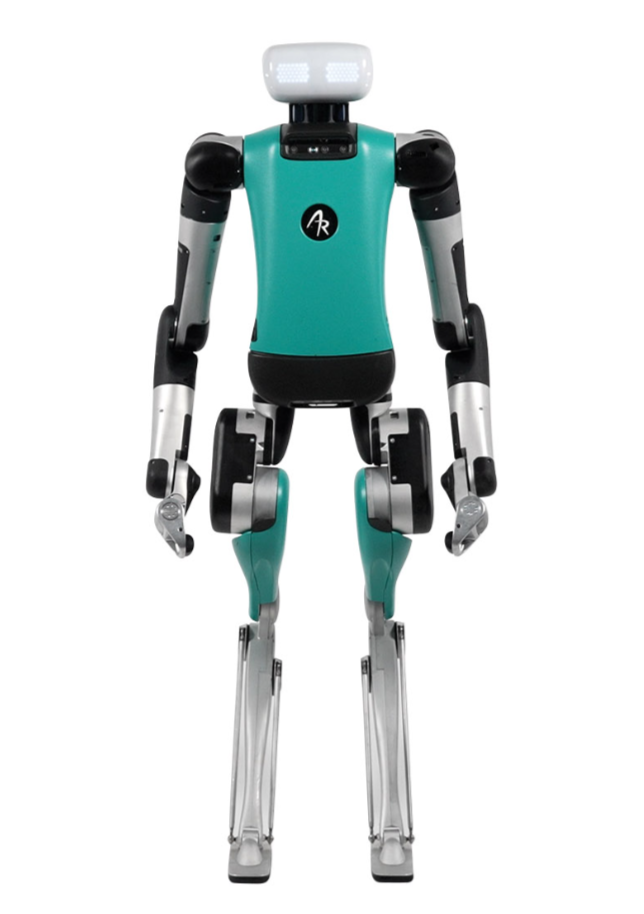

Digit

Agility Robotics

Digit is most accurately described as “bipedal” rather than “humanoid.” It has two legs, but its legs look more like those of an ostrich rather than a human’s. This is a side effect of Agility’s design process, the goal of which was to maximize the efficiency and robustness of legged locomotion.

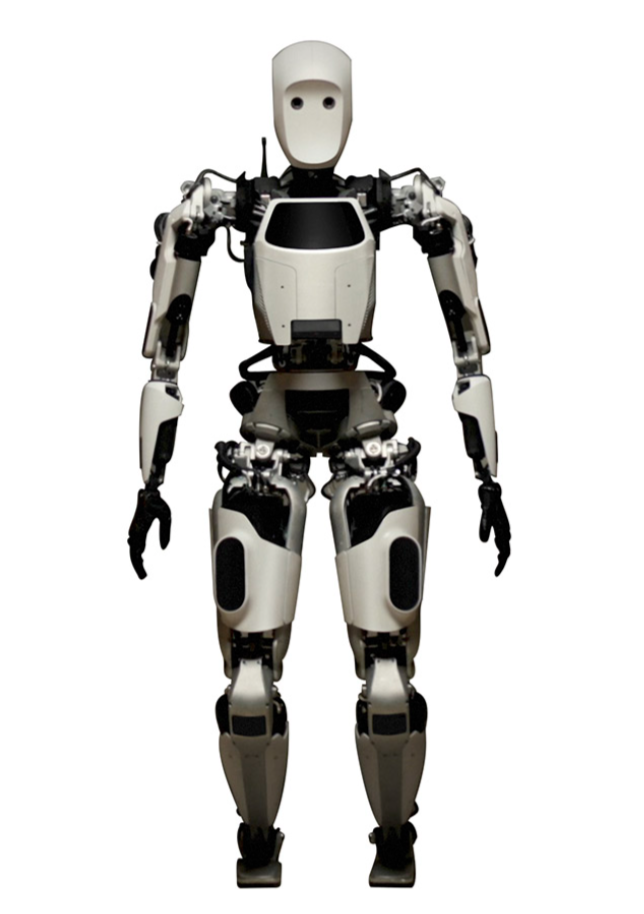

Optimus

Tesla

Tesla has a few unique advantages when it comes to building and deploying robots. The company has substantial experience in battery technology, as well as in sensing and computing for mobile systems. And Tesla is potentially its own first customer for humanoids, finding work for them in its car factories.

Figure 01

Figure

Figure was founded just a few years ago, but its robotics team is very experienced, tracing its heritage back through the DARPA Robotics Challenge. By iterating very quickly through hardware prototypes, Figure expects to demonstrate commercial viability in a real-world use case within the next 18 months, and scale from there.

GR-1

Fourier Intelligence

Singapore-based Fourier Intelligence is already mass-producing its GR-1 humanoid robot. Fourier’s background is in health-care robotics, and the company sees potential applications for GR-1 in medical and rehabilitation contexts, although the robot will also be available to researchers seeking a humanoid development platform.

Apollo

Apptronik

Apptronik has worked on more than half a dozen humanoid robots over the past eight years, including NASA’s Valkyrie. Apollo is the culmination of all this experience and is designed for manufacturability. Apptronik plans to field its robots in 10 pilot projects in 2024, with a full commercial release of Apollo in 2025.

Phoenix

Sanctuary AI

Sanctuary AI’s goal is to “create the world’s first humanlike intelligence in general-purpose robots.” To accomplish this, the company has been collecting extensive amounts of data of humans teleoperating its robots through complex manipulation tasks. Sanctuary AI hopes to leverage that data to train its robots to perform those tasks autonomously.

At PLAEX we are ready for the future of automation!

We Look forward to one day soon having fleets of robots assembling and modifying truly circular and affordable buildings.

Automation is here, and we need it to bridge the labour gap.

We are excited about the immense potential this technology shift represents.